In the world of colors and printing, the YMC(K) color model plays a crucial role. It helps create vibrant, accurate, and detailed prints. Whether it’s a colorful magazine, a book cover, or a product package, YMC(K) is behind many of the beautiful images we see.

Let’s take a closer look at what YMC(K) is, how it works, and why it’s so important in different industries.

1. What is the YMC(K) Color Model?

YMC(K) stands for Yellow, Magenta, Cyan, and Key (which usually means Black). This color model is widely used in printing to create a wide range of colors. While the RGB model mixes red, green, and blue light to create colors on screens, YMC(K) mixes inks to produce colors on paper or other materials.

Here’s how it works:

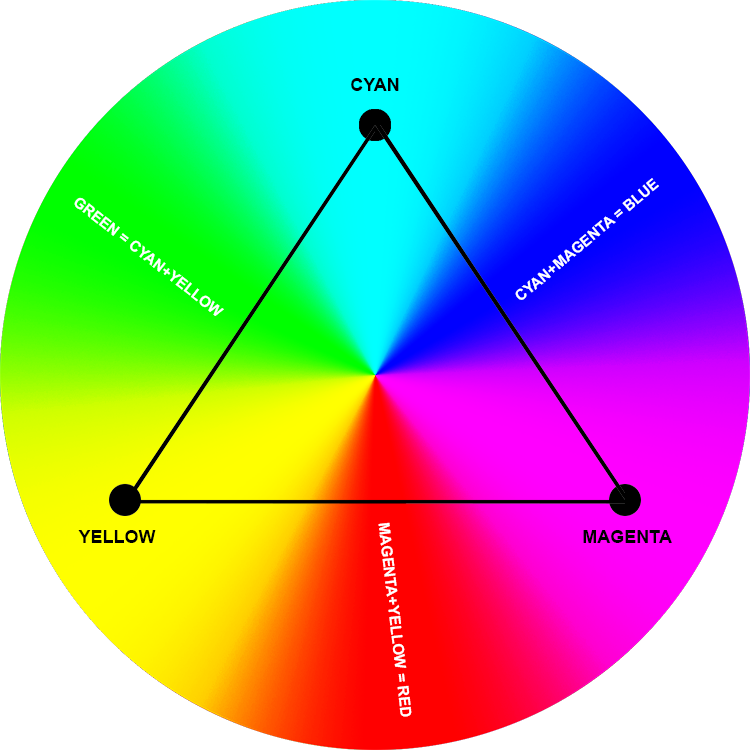

1. Yellow, Magenta, and Cyan are the primary colors in this model. When mixed, they create secondary colors.

- Magenta + Yellow = Red

- Yellow + Cyan = Green

- Cyan + Magenta = Blue

2. Black (Key) is added to deepen the colors and enhance the contrast, making the images look sharp and clear. This black ink helps in making darker shades and outlines more defined, giving depth to the printed images.

2. Why YMC(K) is Good for Printing?

YMC(K) is a powerful tool in printing because it allows for very accurate color reproduction. By carefully controlling how much of each color is used and how they overlap, printers can produce a vast spectrum of colors. This means that they can print everything from bright, bold designs to soft, subtle gradients.

The inclusion of black ink (Key) is particularly important because it adds contrast. For example, in a printed photograph, black ink helps in highlighting details, making the image look more realistic and clear.

3. Where YMC(K) is Used?

YMC(K) printing is used in many different areas, especially where color quality and accuracy are important. Here are some examples:

- Magazines and Books: YMC(K) helps in creating vivid and attractive pages that capture readers’ attention.

- Packaging: From cereal boxes to luxury product packaging, YMC(K) ensures that the colors are consistent and eye-catching.

- Advertising: Whether it’s a billboard or a flyer, YMC(K) printing is key to making sure that the colors stand out and convey the right message.

- Branding: Companies rely on YMC(K) to ensure their logos and brand colors are printed correctly, helping them maintain a consistent brand image.

4. The Benefits of YMC(K) Printing

Using the YMC(K) color model in printing offers several benefits:

- Accurate Color Reproduction: The YMC(K) model ensures that the colors in the final print match the original design as closely as possible.

- Enhanced Detail and Depth: The addition of black ink allows for greater detail, making images and text look sharper and more defined.

- Cost-Effective: YMC(K) printing is efficient because it minimizes ink waste. This makes it a cost-effective option for high-quality printing.

- Wide Color Range: By mixing the basic colors, YMC(K) can produce a wide variety of hues, making it versatile for different types of prints.

However, to get the best results, the printers need to be well-calibrated, and the printing process must follow industry standards. This ensures that the colors remain consistent across different print runs.

5. How YMC(K) Technology is Improving?

Over the years, YMC(K) printing technology has seen many advancements. These improvements have made printing more accurate and flexible. Some of the key developments include:

- Better Ink Formulas: Newer inks provide better color accuracy and are more environmentally friendly.

- Advanced Printing Techniques: Techniques like stochastic screening (which reduces graininess) and variable dot printing (which adjusts the size of ink droplets) have made YMC(K) printing more precise.

- Digital Printing: With the rise of digital printing, YMC(K) has become even more versatile. Digital printing allows for on-demand printing, meaning that companies can print small batches of materials quickly and efficiently.

6. The Future of YMC(K) Printing

As technology continues to evolve, the future of YMC(K) printing looks promising. Here are some trends to watch:

- Hybrid Printing: Combining traditional and digital printing methods could offer even greater flexibility and efficiency.

- Sustainable Inks: As the world becomes more focused on sustainability, the development of eco-friendly inks is likely to grow, making YMC(K) printing more environmentally responsible.

- Augmented Reality: Integrating printed materials with augmented reality could create new, interactive experiences, further expanding the possibilities of YMC(K) printing.

By staying at the forefront of these trends, YMC(K) printing will continue to be a vital tool in producing high-quality, colorful prints.

In the colorful world of printing, YMC(K) plays a key role in bringing designs to life. From magazines to product packaging, this color model is essential for creating vibrant, detailed prints. As printing technology continues to advance, YMC(K) will remain a cornerstone of the industry, helping to turn creative ideas into stunning, tangible products.